nesco dehydrator manual

Nesco Dehydrator Manual: A Comprehensive Guide

Discover a world of preserved flavors! This manual details Nesco dehydrator operation, from setup to troubleshooting, ensuring successful jerky, fruit leather, and snack creation.

Understanding Your Nesco Dehydrator

Welcome to the world of food preservation! Your Nesco dehydrator utilizes a gentle heat and airflow system to remove moisture from foods, extending their shelf life and concentrating flavors. This process doesn’t require cooking, preserving vital nutrients often lost during traditional canning or freezing. Understanding the core principles of dehydration – heat, airflow, time, and food preparation – is key to achieving optimal results;

Nesco dehydrators are designed for versatility, handling fruits, vegetables, meats for jerky, and even creating delightful fruit leathers. The fan, positioned at the base or side (depending on the model), circulates warm air upwards through the food trays. Consistent airflow is crucial; avoid overcrowding trays to ensure even drying. Familiarize yourself with the dehydrator’s components, as detailed in the following sections, to maximize its potential and enjoy homemade, healthy snacks for years to come. Proper understanding leads to delicious outcomes!

Model Variations & Identifying Your Unit

Nesco offers a diverse range of dehydrators to suit various needs and budgets. From the classic round models like the FD-600 to the larger, more advanced options such as the Gardenmaster series, understanding your specific unit is paramount. Key differentiators include capacity (number of trays), wattage (affecting drying speed), and features like digital timers and temperature controls.

To identify your model, locate the model number and serial number typically found on a sticker on the back or bottom of the unit. Refer to this number when ordering replacement parts or accessing specific online resources. Some models, like the American Harvest Jerky Works Kit, are specialized for specific applications. Knowing your model allows you to access the correct manual and troubleshooting guides. Variations also exist in tray materials and fan placement, impacting performance. Accurate identification ensures optimal operation and longevity of your Nesco dehydrator.

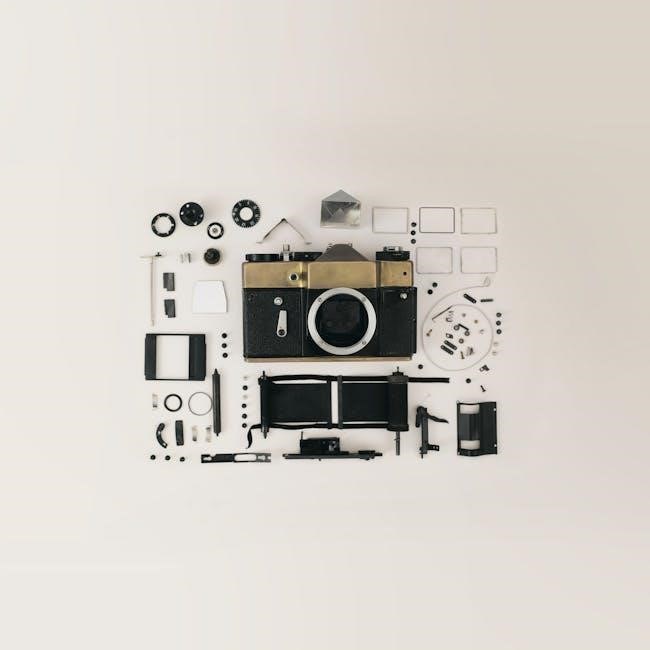

Key Components & Parts Breakdown

A Nesco dehydrator comprises several essential components working in harmony. The base houses the heating element and fan, crucial for circulating warm air. Trays, typically made of plastic or mesh, hold the food during dehydration; models vary in the number of included trays. The top cover directs airflow and helps maintain consistent temperature. Some units feature a flexible on/off switch, while others boast digital controls.

Understanding each part aids in maintenance and troubleshooting. Replacement trays are readily available, and the fan motor is a key component for consistent drying. The convection oven models, like the JS-3000T, include additional features like a reflector bowl. Regularly inspect the power cord for damage. Familiarize yourself with the location of vents to ensure proper airflow. Proper part identification is vital when ordering replacements or seeking repair assistance, ensuring your Nesco dehydrator functions optimally.

Setting Up Your Nesco Dehydrator

Begin by preparing a stable, level surface. Assemble the unit following the included diagrams, ensuring proper tray alignment for optimal airflow and efficient dehydration.

Initial Preparation & Cleaning

Before your first use, thoroughly inspect all Nesco dehydrator components. Remove any packaging materials, stickers, or remnants from shipping. Wash all removable parts – trays, liners (if applicable), and the base – in warm, soapy water. Avoid abrasive cleaners, as they can scratch the surfaces.

Rinse thoroughly and allow all parts to air dry completely before reassembling. The heating element and fan assembly should be wiped clean with a damp cloth; never immerse these components in water. Ensure the fan is free from obstructions. A clean dehydrator is crucial for preventing unwanted flavors and maintaining food safety.

Inspect the power cord for any damage. If damage is present, do not use the dehydrator and contact Nesco customer support. Proper initial cleaning sets the stage for years of successful dehydrating, preserving the quality and taste of your homemade snacks and meals. Remember to consult the full manual for specific cleaning recommendations related to your model.

Assembling the Dehydrator – Step-by-Step

Begin by placing the base of your Nesco dehydrator on a stable, level surface. Next, carefully position the fan assembly onto the base, ensuring it sits securely. Attach the desired number of trays onto the support posts, starting with the bottom-most tray. Trays should slide or clip onto the posts easily; avoid forcing them.

If using liners, place them onto the trays before adding food. Some models feature a top cover; if included, place it on top of the assembled trays. Ensure proper airflow by not overcrowding the trays with food. Maintain space between items for optimal dehydration.

Double-check that all components are correctly aligned and securely fastened. A properly assembled dehydrator ensures even drying and efficient operation. Refer to your model’s specific diagram in the manual for visual guidance. Incorrect assembly can lead to uneven results or potential damage to the unit.

Powering On & Basic Operation

To initiate operation, plug the Nesco dehydrator into a grounded electrical outlet. Most models feature a simple on/off switch, typically located on the base. Once powered on, the fan should begin circulating air. Some units offer temperature control settings; consult your manual for specific adjustments.

Generally, lower settings are ideal for fruits and vegetables, while higher settings are suited for meats. Load prepared food onto the trays, ensuring adequate spacing for airflow. Set the desired dehydration time based on the food type and thickness – refer to recipe guides for recommendations.

Avoid opening the dehydrator frequently during operation, as this can disrupt the drying process. Periodically check the food’s progress, rotating trays if necessary for even drying. Once dehydration is complete, power off the unit and allow it to cool before disassembling and removing the dried food.

Dehydrating Food: Techniques & Tips

Master food preservation! Learn optimal preparation methods for fruits, vegetables, and meats, alongside expert tips for creating delicious, long-lasting snacks and jerky.

Preparing Fruits & Vegetables

Achieving optimal results with your Nesco dehydrator begins with proper fruit and vegetable preparation. Thoroughly wash all produce to remove dirt and residue. For fruits like apples and bananas, consider pretreating with lemon juice to prevent browning and maintain vibrant color during the dehydration process. Slicing consistency is crucial; aim for uniform thickness – typically ¼ inch – to ensure even drying across all pieces.

Vegetables often benefit from blanching before dehydration. Blanching involves briefly immersing vegetables in boiling water, then immediately cooling them in ice water. This stops enzyme action that can cause discoloration and flavor loss. Root vegetables, such as carrots and beets, require longer dehydration times than softer fruits. Arrange slices in a single layer on the dehydrator trays, ensuring adequate air circulation. Overcrowding can lead to uneven drying and potentially spoilage. Remember to rotate trays periodically for consistent results. Experiment with different seasonings and marinades to enhance the flavor of your dehydrated fruits and vegetables!

Dehydrating Meats for Jerky

Creating delicious, homemade jerky with your Nesco dehydrator requires careful attention to safety and preparation. Begin with lean cuts of meat – flank steak, round steak, or venison are excellent choices. Partially freeze the meat for easier slicing into ¼-inch thick strips, always cutting with the grain for a chewier texture. Marinades are key to flavor and tenderization; ensure they contain sufficient salt for preservation.

Before dehydrating, consider a pre-treatment to eliminate potential bacteria. Some recommend a brief boil (5-10 minutes) or a vinegar/salt solution soak. Arrange marinated meat strips in a single layer on the dehydrator trays, avoiding overlap. Dehydration times vary based on meat thickness and desired texture, typically ranging from 4 to 8 hours. The jerky is done when it bends without breaking, but remains pliable. Allow jerky to cool completely before storing in an airtight container. Proper dehydration and storage are vital for food safety!

Making Fruit Leather & Snacks

Unlock a world of healthy and delightful snacks with your Nesco dehydrator! Fruit leather is incredibly simple: puree your favorite fruits – apples, berries, mangoes – until smooth. A touch of lemon juice prevents browning. Spread the puree thinly (about ¼ inch) onto a non-stick dehydrator tray or a parchment paper liner. Dehydrate for 6-12 hours, or until the leather is pliable but not sticky.

Beyond fruit leather, explore vegetable chips! Thinly slice zucchini, sweet potatoes, or beets, lightly toss with olive oil and seasonings, and dehydrate until crispy. Apple rings are another fantastic option – core and slice apples, sprinkle with cinnamon, and dehydrate. Remember to rotate trays during dehydration for even drying. Properly dehydrated snacks offer a convenient and nutritious alternative to store-bought treats, perfect for hiking, lunchboxes, or a quick energy boost!

Troubleshooting Common Issues

Resolve dehydration challenges swiftly! This section addresses problems like the unit not powering on, uneven drying, and temperature inconsistencies, ensuring optimal performance.

Dehydrator Not Turning On

If your Nesco dehydrator fails to power on, begin with the simplest checks. Ensure the power cord is securely plugged into both the dehydrator and a functioning wall outlet. Test the outlet with another appliance to confirm it’s delivering power. Inspect the power cord itself for any visible damage, such as cuts or fraying – a damaged cord presents a safety hazard and should be replaced.

Next, examine the dehydrator’s base for a reset button or a power switch that might be in the ‘off’ position. Some models feature an automatic shut-off mechanism that may activate if the unit overheats; allow it to cool completely before attempting to restart. If the unit still doesn’t respond, consult the warranty information, as a faulty power supply or internal component may require professional repair or replacement. Avoid attempting to disassemble the unit yourself, as this could void the warranty and pose a safety risk.

Finally, double-check that all components are correctly assembled. While less common, improper assembly can sometimes prevent the unit from powering on. Refer to the ‘Assembling the Dehydrator’ section for guidance.

Uneven Drying & Temperature Problems

Experiencing uneven drying or inconsistent temperatures with your Nesco dehydrator? Several factors could be at play. Overloading the trays is a common cause; ensure adequate space between food pieces for proper air circulation. Rotate the trays periodically during the drying process – typically halfway through – to promote even exposure to the heat source.

Check that the dehydrator is placed on a level surface, as an uneven base can affect airflow. Avoid placing the unit in direct sunlight or near heat sources, which can disrupt temperature regulation. If using a model with adjustable temperature settings, verify that the selected temperature is appropriate for the food being dehydrated.

Inspect the heating element for any obstructions or damage. A malfunctioning thermostat could also be the culprit, leading to inaccurate temperature readings. If problems persist, consult the troubleshooting section or contact Nesco customer support for assistance. Consistent monitoring and proper food preparation are key to optimal results.

Cleaning & Maintenance Guide

Regular cleaning is crucial for maintaining your Nesco dehydrator’s performance and hygiene. Always unplug the unit before cleaning. Removable trays and inserts can typically be washed with warm, soapy water; avoid abrasive cleaners that could damage the surfaces. Rinse thoroughly and allow to air dry completely before reassembling.

The dehydrator base should be wiped down with a damp cloth. Avoid immersing the base in water. For stubborn food residue, a mild degreaser can be used, followed by a clean water rinse. Inspect the fan for dust accumulation and carefully remove it with a soft brush or vacuum attachment.

Periodically check the power cord for any signs of damage. Store the dehydrator in a clean, dry place when not in use. Proper maintenance extends the lifespan of your appliance and ensures food safety. Refer to the full manual for specific cleaning instructions related to your model.

Safety Precautions & Warranty Information

Prioritize safety by following guidelines. Nesco offers warranties on its dehydrators; registration details are vital for claims and coverage verification—read carefully!

Important Safety Guidelines

Always unplug your Nesco dehydrator before cleaning or attempting any maintenance. Never immerse the base in water or other liquids, as this presents a serious electrical hazard. Ensure the unit is placed on a stable, heat-resistant surface away from flammable materials during operation.

Supervise children closely when the dehydrator is in use. The exterior surfaces can become hot during operation, posing a burn risk. Avoid using extension cords if possible; if necessary, use a heavy-duty cord rated for the appliance’s wattage.

Do not operate the dehydrator if the power cord or plug is damaged. Inspect regularly for wear and tear. Never attempt to repair the unit yourself; contact Nesco customer support for assistance. Proper ventilation is crucial; ensure adequate airflow around the dehydrator during use.

Be cautious when handling hot food trays. Use oven mitts or pot holders to prevent burns. Avoid overloading the dehydrator, as this can affect drying performance and potentially damage the unit. Always allow the dehydrator to cool completely before storing.

Nesco Warranty Details & Registration

Nesco offers a one-year limited warranty against defects in materials and workmanship from the date of original purchase. This warranty covers parts and labor for repairs or replacement, at Nesco’s discretion. Damage resulting from misuse, accidents, unauthorized repairs, or normal wear and tear is not covered.

To initiate a warranty claim, retain your proof of purchase and contact Nesco customer support. You may be required to return the defective unit for inspection. Warranty service is available only to the original purchaser and is non-transferable.

Register your Nesco dehydrator online at the official Nesco website to expedite warranty claims and receive product updates. Registration allows Nesco to contact you regarding safety recalls or important product information. Keep your registration confirmation for your records.

Extended warranties may be available for purchase separately. Refer to the Nesco website or authorized retailers for details. This warranty provides peace of mind, ensuring your investment is protected against manufacturing defects.